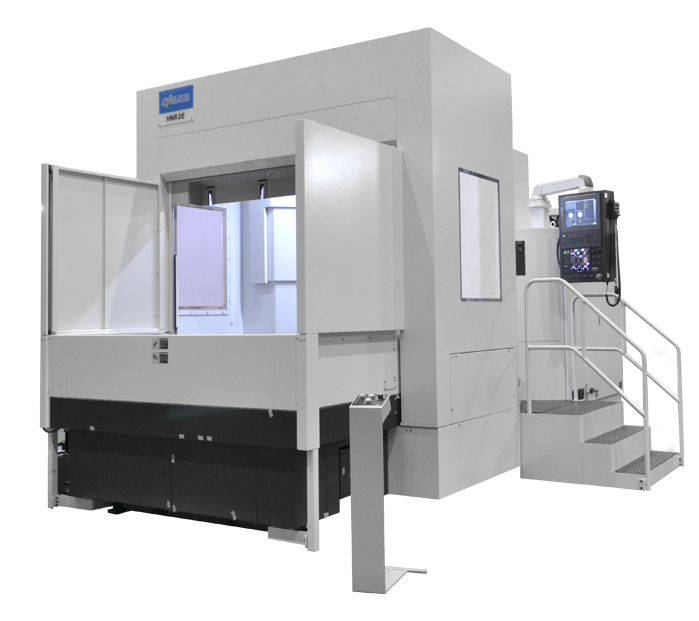

HN63E-Ti Heavy Duty Boxway Horizontal Machining Center (HMC) Designed for Machining Titanium and Other Hard Machining Materials

- Heavy duty boxway machining center designed for ultra low frequency machining.

- Solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Wide induction hardened boxways for long-term accuracy and rigidity.

- All axes hand scrapped by highly experienced technicians.

- Gear driven spindles that generate extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

| SPECIFICATIONS | ITEM | HN63E-Ti | |

|---|---|---|---|

| TRAVEL & WORK CAPACITY | X axis travel (longitudinal table) | 1080 mm | 42.5" |

| Y axis travel (vertical head) | 930 mm | 36.6" | |

| Z axis travel (column in & out) | 830 mm | 32.7" | |

| Max Work / Swing Diameter | 1080 mm | 42.5" | |

| Max Work / Height | 1000 mm | 39.4" | |

| TABLE | Table working surface | 630 x 630 mm | 24.8" x 24.8" |

| Table increments [option] | 1° [0.001°] | 1° [0.001°] | |

| Maximum mass on pallet | 1200 kg | 2640 lbs | |

| Maximum mass on pallet NC table | 1200 kg 1500 kg |

2640 lbs 3300 lbs |

|

| SPINDLE | Spindle speeds | 3500 min-1 | 3500 rpm |

| Spindle taper | CAT 50 BIG PLUS HSK100A option |

CAT 50 BIG PLUS HSK100A option |

|

| FEEDRATE | Rapid traverse X axis | 30 m/min | 1181 ipm |

| Rapid traverse Y axis | 30 m/min | 1181 ipm | |

| Rapid traverse Z axis | 30 m/min | 1181 ipm | |

| AUTOMATIC TOOL CHANGER (ATC) | Tool magazine capacity | Chain 62 [88/128/175/255] Matrix [126/178/230/308] |

Chain 62 [88/128/175/255] Matrix [126/178/230/308] |

| GENERAL | Machine weight approx. | 21500 kg | 47300 lbs |

| Control | Fanuc 30iB (31iB) | Fanuc 30iB (31iB) | |

All specifications subject to change without notice.

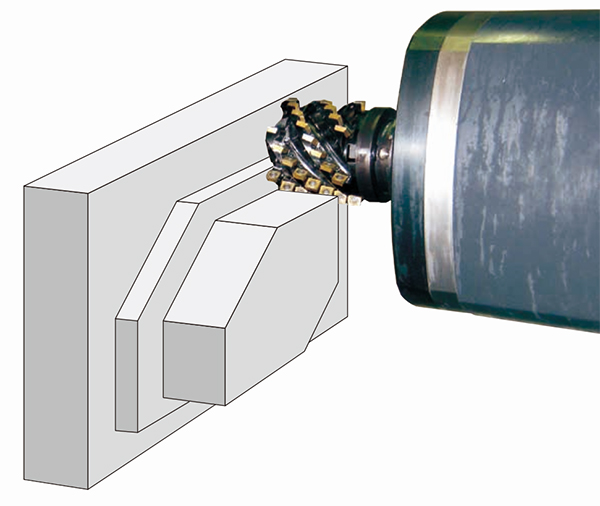

Efficient Machining of "Difficult Material to Cut"

Global industrial demand to machine hard metals has been drastically increased based upon historical material innovation for the production industries. Niigata has classified the materials as "Difficult material to cut" such as Titanium, Inconel and Hastelloy, etc. Niigata's constant research and development achieved the solution for high efficient and profitable parts machining for these hard materials.

As a world leader of the horizontal machining center, NIIGATA is proud to declare that the new HN63E-Ti PRO Package Package will satisfy requirements of your production needs with "Difficult material to cut".

Titanium Machining

One of the remarkable hard material on high demand is Titanium generally called 64Ti, 5553Ti., etc. Niigata has been focusing on Ti material as one of most demandable materials in the market. Extensive knowledge through test cutting by the Niigata engineering team is ready to support your production challenge.

The Machine Design Criteria

Niigata's tradition, true Heavy Duty BOX WAY style Horizontal Machining Center model HN-series are highly regarded worldwide as the most capable hard metal cutting HMC in the industry. The fundamentals of machine design have been proved already for hard metal machining. Key development criteria for Ti PRO Package was to enhance and up-grade key machine components to achieve the following machine capabilities.

- Low frequency machining

- Superior rigidity and stiffness of the machine

- Greater axes thrust

- High torque geared spindle interface with tool

- Longevity of tool life